At its most basic definition a wood veneer is a thinly sliced timber glued to a core panel to enhance its appearance.

The earliest known example of veneered panels goes back 4,000 years, to the Ancient Egyptians. Then, as we still do now, the Egyptians used veneers of rare and expensive woods to improve the appearance and increase the value of the solid timber used to create plain furniture.

Modern production methods have improved efficiency and consistency but has not changed the basic principles nor the benefits in creating and applying veneered panels to bespoke furniture. Modern manufacturing, design and technology has produced alternative veneer products that can provide a greater variety of finish through differing manufacturing methods.

For over 50 years, Griffiths & Hood has been at the forefront of veneered panels and furnishings. Take a look at an overview of our production materials below.

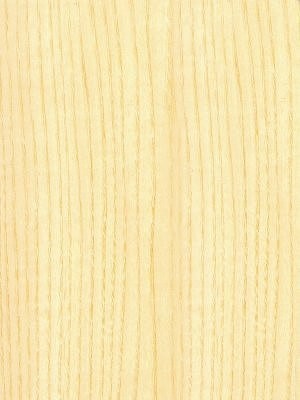

Natural Veneer

Natural veneers are a thin layer of real hardwood taken from timber that is a product of its individual environment. Location, climate and soil are a few of the factors that impact each tree individually, meaning each natural veneer is a unique piece. The colour of veneer is typical to the tree that produces it, however it can be stained to achieve non-natural colours.

When used and sourced correctly, veneering makes more use of the original timber than in the creation of one solid piece. Veneering timber is an economically and ecologically sustainable approach to furniture production.

Natural veneer will produce a spectacular and unique creation every time, no two pieces can be identical; even veneers produced from the same batch of trees will be slightly different.

Below is a small selection of available veneers, should you have a request for one not listed please do get in touch with us - chances are we have used it before!

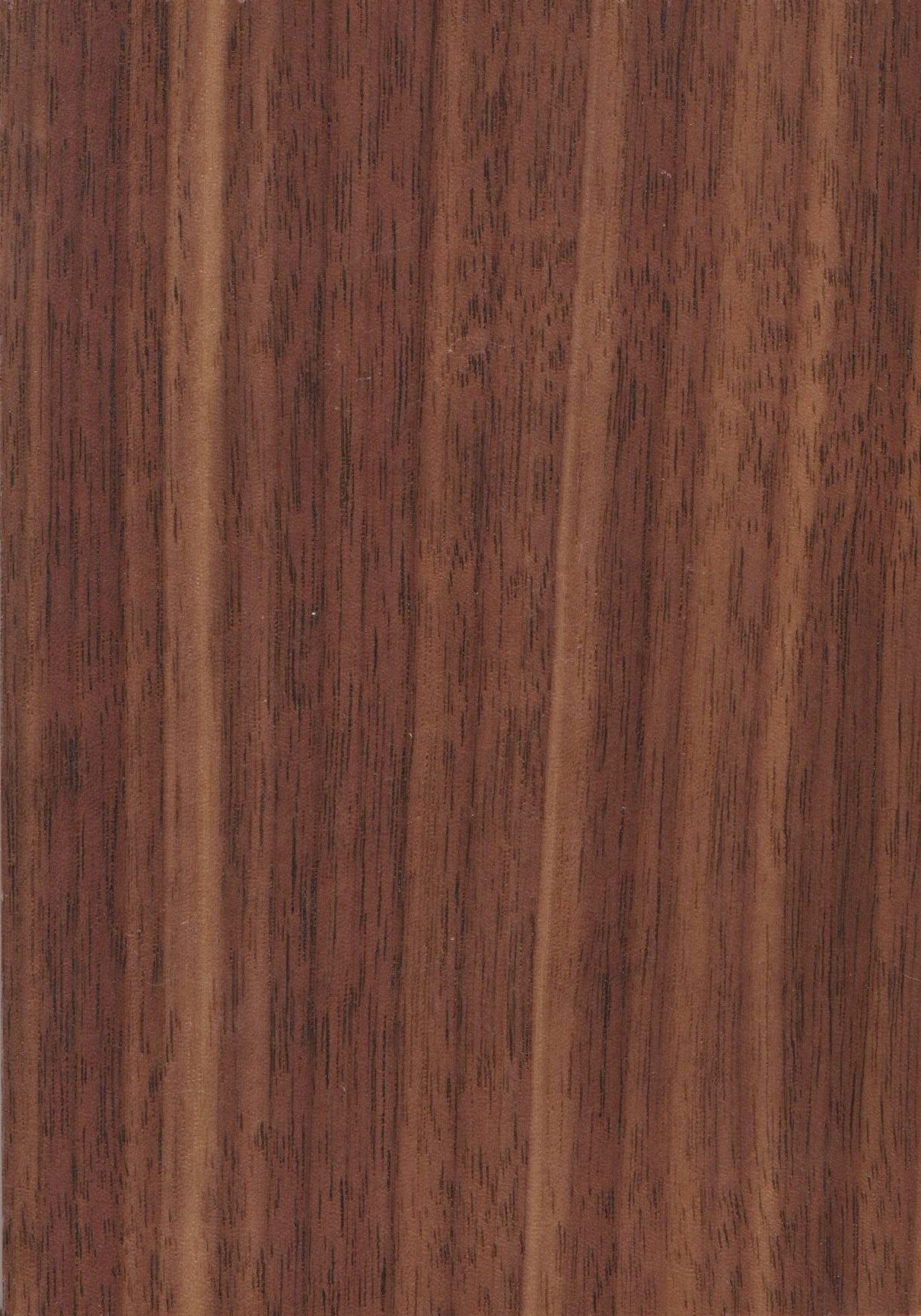

Engineered Veneer

Engineered Veneer is a man-made, manufactured version of natural veneer. This veneer was initially created to reduce the carbon impact of classic methods of creating veneered panels. It also allows for commercial production with identical results every time.

Some engineered veneer products use renewable and sustainable species of tree. Others use new 3D printing technology. The method is the same in both products: stacks of thin material are dyed, then dried and glued together, before being re-cut and re-glued to produce a desired pattern.

The final product creates an emulated version of natural wood grains. Engineered veneer allows for the creation and production of new designs not to be found in natural veneer. Engineered veneers offer a veneer look and texture that can be mass produced to ensure a range has consistency throughout.

Engineered Veneer comes in hundreds of variations, this list will provide an idea of the range and variety available. Should you have a request for one not listed please do get in touch with us - chances are it will be available!